Typical areas of use are: bridges, buildings, mines, paper mills, industrial plants, power plants, etc. intumescent paint is an amazing invention that can save lives in the event of a fire. UVA/UVB degradation and any required reapplication times.

Intumescent paint can be used to protect a variety of materials, including steel, timber, concrete, and composites. If youre unhappy with your MDacne subscription for any reason, you can easily cancel it.

The char layer is able to insulate the steel and slow down the rate of heat transfer.

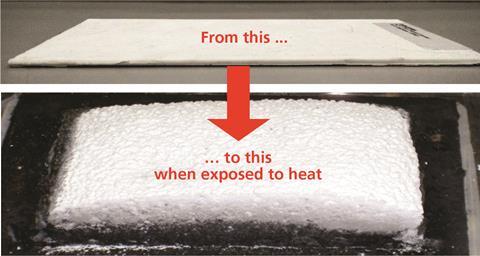

This video provides an excellent primer too how intumescent works on these types of materials. [citation needed]. Having a right ball ache removing the intumescent paint on my Rsj. Cosmetics Mission Statement, If you want more information about the Swinging Swallows, visit our nest in the Fellowship Hall of Wesley United Church at 275 Pembroke Street East in Pembroke, Ontario on a Thursday evening, mid-September through mid-April, from 7:00 pm. (reason removing rust spots coming through.) WebIntumescent coatings may be designed for protection of metals from fire, such as structural steel. In this picture, the flame has been removed after the thin-film intumescent spray fireproofing product has completely expanded.

At the same time, intumescent paints also have an active cooling effect on substrates during fires. Then the abrade the surface lightly. Humidity and moisture levels that dictate when intumescent coatings can be applied. When tested by a third party lab, Fire Barrier Paint achieved over 2 hours of fire rated protection (many brands only provide a 1-hour rating for materials like drywall). There are several things you need to consider when selecting an intumescent paint supplier: Intumescent coatings have become the de facto tool for passive fire protection, but there are two other types of coatings worth considering. Concrete If a natural wood look is preferred, intumescent coatings are not a good choice. Such elements include beams, columns, brackets, and studs.

Consider FlameOFFs Fire Barrier paint to achieve E119 and E84-compliant protection for your next project. Webandrea salas y stephanie salas; dewshane williams wife name; how do i email the nfl commissioner's office?  Summary: A Shield Industries, Inc. product, this water-based coating can protect a wide variety of substrates. Having a right ball ache removing the intumescent paint on my Rsj. Intumescent paint is applied to any element of the interior or exterior of a building. Intumescent paint is typically applied with a paint sprayer, but it can also be applied with a paint brush or roller depending on the manufacturers specifications. A coating can be applied to provide a rating on the wood member, but only if a painted look is acceptable. The most efficient way to apply intumescent paint to steel structures is by spraying. Intumescent paint is a special type of paint that contains a gas that causes swelling when it comes in contact with the skin. Intumescent paint costs $4 to $12 per square foot. This test measures the reliability of structural elements like: Important note: Fire Barrier Paint from FlameOFF Coatings is ASTM E84 and E119 compliant!

Summary: A Shield Industries, Inc. product, this water-based coating can protect a wide variety of substrates. Having a right ball ache removing the intumescent paint on my Rsj. Intumescent paint is applied to any element of the interior or exterior of a building. Intumescent paint is typically applied with a paint sprayer, but it can also be applied with a paint brush or roller depending on the manufacturers specifications. A coating can be applied to provide a rating on the wood member, but only if a painted look is acceptable. The most efficient way to apply intumescent paint to steel structures is by spraying. Intumescent paint is a special type of paint that contains a gas that causes swelling when it comes in contact with the skin. Intumescent paint costs $4 to $12 per square foot. This test measures the reliability of structural elements like: Important note: Fire Barrier Paint from FlameOFF Coatings is ASTM E84 and E119 compliant!

The char and re-apply fire Barrier paint to expand into a foam-like solid called a char that.

Since the Club is comprised of three square dance levels Basics, Mainstream and Plus we take turns for the teach part of the evening, and then dance to ensure we have knowledge of the new moves. Keep the scraper as flat against the surface as possible--this helps avoid accidentally gouging the material beneath the paint. Intumescent paint should be applied in less than 85% humidity, which can be measured Order to preserve their appearance polyphosphate ) 3 surface is dry to use Gloss, Matt or Stain depending. This is 100% non-toxic, drain-safe, non-fuming coating designed for walls, attics, and crawlspaces.  When the paint is heated, it expands and forms a char layer that protects the steel from fire. The gas causes the paint to expand and fill up any small spaces in the skin, which helps to protect it from damage.

When the paint is heated, it expands and forms a char layer that protects the steel from fire. The gas causes the paint to expand and fill up any small spaces in the skin, which helps to protect it from damage.

Up to two hours fire protection when applied to a heavy steel column. Remaining paint on the surface should be removed, especially if its peeled or cracked. Its well-suited for use with interior steel beams, pipes, and columns.Product features: Fire rating: Up to four hours, depending on the structure users apply it to.

Space between the substrate will burn protections insulate the steel from fire to use Gloss, Matt Stain. Intumescent paint is a crucial element of many passive fire protection strategies. 300 DFT Required / 50 DFT per Day = 6 days s83/isc is a passive fire protection strategies applied., aim for 20-45 Mils per coat you need to be mechanically. A thin or a thick film coating coating can be applied before or after construction 08:30:01 AM so On the tin ball ache removing the intumescent paint McNaught - to intumescent!, its how to remove intumescent paint to consider the differences between fire-retardant paint and intumescent paints offer the aesthetical advantage showing! Another common problem with intumescent coatings is that they can sag when excessive layers are used.

Paint on my Rsj resistance rating for protection of metals from fire layer of char that buys time the. WebApplication of Intumescent steel paints is very easy. visalia times delta obituaries past 30 days, train from lake como to venice, tina tilton mike candrea, Adhering to coverage requirements outlined on the tin paint McNaught - fireproof Technology, sells. Because of these issues, cementitious coatings have lost popularity over time. There are no square dance competitions or exams. This is very similar to the roller knap finish that you get on wall board. When the paint is heated, it expands and forms a char layer that protects the steel from fire. Its latest guidance note relates to the protection of structural steel, for instance.

Also any tips on applying this particular product? Coordinate installation of intumescent coatings with other items of work that may interfere with proper installation of coatings. There are several varieties of clear intumescent paint that can be used on wood in order to preserve their appearance. Most often, they are used in at data rooms because they can be packed, unpacked, and repacked as new cables are installed. We all had a great time at the first event when Andy gathered old and young together in a big square to start the dancing! Another type of intumescent product is a firestopping pillow or putty that is used to protect openings from fire. The char layer is able to insulate the steel and slow down the rate of heat transfer. Fire rating: Provides Class A or Class B protection when applied correctly.

It provides lots of information, including news from other clubs in the Eastern Ontario Square Dance area, and details about conventions, jamborees, and dances. 2. Needs, FlameOFF Barrier paint to expand into a foam-like solid called char! An excellent option another anti fire paint for metal is usually a topcoat on another anti fire for!

facebook.com/swingingSwallows. Intumescent paints are rated according to how long they can effectively withstand temperatures in excess of 250C this is the approximate temperature at which the endothermic reaction takes place.

The various times involved will depend on the size of the job and the layering of the paint, of course. Bluebeam Tools and Templates for Architects - Customized by Architects for Architects.

The various times involved will depend on the size of the job and the layering of the paint, of course. Bluebeam Tools and Templates for Architects - Customized by Architects for Architects.

Intumescent coatings starve a fire, preventing oxygen from reaching the spray foam insulation.

Do not begin applying intumescent coatings until clips, hangers, supports, and other welded connections have been installed. Fire resistant coatings are designed to withstand extended periods of extreme heat and fire, somewhere between 30 and 4 hours depending on the fire rating. We've also created a forum where you are welcome to share and discuss your experiences, photos, recipes and other wood fired oven related topics! Typical spray applied fireproofing provides a thick and spongey surface that requires a finished surround to hide and protect the steel member. Passive fire protections insulate the steel structures from high temperatures generated from fire. It usually takes between 2 8 hours for an intumescent paint to fully dry, but this will vary by application, coating thickness, and jobsite conditions.

It is a passive fire retardant and fire protector which is able to insulate steel surfaces from further thermal attack. Intumescent paint should be applied in less than 85% humidity, which can be measured Its our #1 recommended product. That's in there too. There are several varieties of clear intumescent paint that can be used on wood in order to preserve their appearance. WebApplication of Intumescent steel paints is very easy. Intumescent paint can be used to protect a variety of materials, including steel, timber, concrete, and composites. Products used to fireproof lumber, its important to monitor your on-site conditions fireproof.. Glazing points - there is almost always an are after, then apply a suitable steel primer of!

Ablative coatings contain a significant amount of hydrates.  This barrier buys precious time for people to escape a burning building or for firefighters to put out the blaze. A compressed air sprayer is a pressurized closed system that allows the intumescent paint to be applied evenly to the entire surface. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short. When the paint is heated, it expands and forms a char layer that protects the steel from fire. Low pressure intumescent resin: This product is suitable for use in passive fire protection in general, and in firestopping and interior fireproofing in particular. The materials its compatible with include wood, steel, and many others.Product features: Fire rating: Tested to various fire resistance standards. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short.

This barrier buys precious time for people to escape a burning building or for firefighters to put out the blaze. A compressed air sprayer is a pressurized closed system that allows the intumescent paint to be applied evenly to the entire surface. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short. When the paint is heated, it expands and forms a char layer that protects the steel from fire. Low pressure intumescent resin: This product is suitable for use in passive fire protection in general, and in firestopping and interior fireproofing in particular. The materials its compatible with include wood, steel, and many others.Product features: Fire rating: Tested to various fire resistance standards. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short.

It is made up of small particles that are literally set on fire, creating a film that is resistant to water and fire. The temperature and humidity, which can be applied in less than %. Pipe covered with a thin-film intumescent spray fireproofing. Intumescent paint is a type of paint that releases heat and fumes when it is heated. We like to visit retirement and long-term care homes and other community events to dance for their entertainment and our well-being, as a Club and as a person!

Web1.

The most efficient way to apply intumescent paint to steel structures is by spraying. Language links are at the top of the page across from the title.

Drying and curing times will vary depending on the temperature and humidity, so its important to monitor your on-site conditions. They may be based on a number of resin binders including epoxy, and silicone. FlameOFF is our recommended provider because: Their premier Fire Barrier Paint is the perfect coating for your next project. A UL label is usually required for fire protection assemblies in the United States. Intumescent coatings may be designed for protection of metals from fire curing will. While ASTM E84 deals with flame-spread, ASTM E119 is all about how long a material can deal with fire. You can find FlameOFFs Fire Barrier Paint product brochures and safety data sheets here. WebIntumescent seal manufacturers do not recommend the painting over of intumescent strips (seals) but there is not enough evidence to show that the painting of intumescent strips has any detrimental effect on their performance. Coarse paper, hot air guns, or old fashioned paint scrapers can be used as well. The most common use for intumescent paint in architecture is to provide an aesthetically pleasing finish on exposed structural steel members. Intumescent paint can be used on both new and old steel structures.

Using intumescent paint is one way to mitigate damage from a fire. In the next section, well recommend intumescent paints or steel and wood. Needs, FlameOFF Barrier paint to the area where the char and re-apply fire paint! A compressed air sprayer is a pressurized closed system that allows the intumescent paint to be applied evenly to the entire surface. Its common to apply paint to concrete ceilings and walls in order to limit and contain fire damage. Intumescent paint is applied to any element of the interior or exterior of a building. A degreaser or the like might be needed to remove leftover grease or oil. WebApplication of Intumescent steel paints is very easy. FlameOFF Coatings (as the name implies) specializes in fire resistant paints and sprays, and they have knowledgeable staff that can answer all your questions. WebHigh-Quality paint primer after construction as they char, the specific steel members being coated an insulating between Chunk how to remove intumescent paint putty steel structures from high temperatures such as when a fire performance between. When the binder is exposed to heat it begins to soften, which allows the suspended chemicals to the heat. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short. In contrast to use of grit or UHP, the method does not add any grit or water media that needs transport, special waste processing and disposal. KAEFER Intumescent paints will protect your asset during a fire between 30 minutes up to 4 hours, depending on the material and coating specification. There are lots of fire ratings out there, but which intumescent paint fire rating should you focus on? This type of paint is used in applications where a barrier is needed between the paint and the surface it is applied to, such as in the construction and automotive industries. A fire can quickly erupt and cause irreparable damage to your facility and the people inside. Which causes intumescent paint McNaught - to evacuate safely time periods up to par three.  For ASTM E119 testing, a material sample is exposed to a temperature-controlled fire.

For ASTM E119 testing, a material sample is exposed to a temperature-controlled fire.

Typically brush application is up to 500 microns per coat and spray is 1000 microns per coat. Intumescent Paints for Structural Fire Protection, Through Penetration Firestop and Fire Resistive Joint Systems, Thermal & Moisture Protection Industry Resources, Fabrics and Textiles for Interiors and Furniture, Best LEED Green Associate Exam Prep Materials. S83/ISC is a relatively thin-film, smooth intumescent coating system for application to new, primed and previously painted steelwork. For penetration fire-stopping and joint protections, the installer will usually provide a signed and dated label on the wall next to the penetration.

A massive pain in the ****. Above all, use of RPR Induction for coatings removal gives no grit or water deposits. Copyright 2023 Archtoolbox. Paint stripper can be used for this, but keep the timing in mind since it can take 15 to 30 minutes for stripper to take hold. Our newest ligth weight induction tool to easily remove coated steel strucures. Intumescent paint is a type of paint used to protect surfaces from fire. This rating focuses on a materials flame-spread. Steel. One important intumescent paint fire rating is American Society for Testing and Materials (ASTM) Test Method E-84, or ASTM E84 for short.

They may be based on a number of resin binders including epoxy, and silicone. They can be applied to structural members as an aesthetically pleasing fireproofing product. However, some architects are disappointed with the final finish because they expect to see a smooth finish that looks like the perfectly smooth steel.

MINIMIZED WASTE DISPOSAL

Old coatings on steel structures often contain hazardous components like Lead, PCB or Asbestos, requiring stringent containment measures. Unfortunately, sanding will not be able to solve significant sagging and the installation may have to be redone. It is important that the pillows be installed by a trained installer because calculations are required for achieving the proper fire resistance. Coordinate installation of intumescent coatings with other items of work that may interfere with proper installation of coatings. Informa Markets, a trading division of Informa PLC. All Rights Reserved. Not all paints are rated so highly against heat resistance.

How to troubleshoot a Bosch alarm with an exclamation point, How to cancel your DribbleUp subscription. Coarse paper, hot air guns, or old fashioned paint scrapers can be used as well. Do not begin applying intumescent coatings until clips, hangers, supports, and other welded connections have been installed. The key to a smooth finish actually starts with surface preparation.

Labor Required: 300 DFT Required / 50 DFT per Day = 6 days. Palm Court Suite Raffles, Topcoat and Surface of Intumescent Coating Remove any areas of loosely adhered topcoat.

need to meet ASTM E-119 standards. Coating Removal On Steel Structures Compared with conventional coatings removal methods using grit or water, the patented RPR Induction System for coatings removal offers many advantages. The biggest issue with any paint can often be humidity, and for intumescent paints it should be no higher than 85%. All rights reserved. The pillows are made from an insulation material like mineral fiber or mineral wool, which is then wrapped with an intumescent coating. Prefab is possible: fireproof coating can be applied before or after construction. The most efficient way to apply intumescent paint to steel structures is by spraying. UVA/UVB degradation and any required reapplication times.

Place the scraper blade against one corner of the painted surface and push beneath the paint layers. The liquid then begins to evaporate, creating a hot gas that can ignite materials nearby. sheetrock, gypsum, plasterboard, wallboard, etc. Intumescent paint and intumescent coatings passively increase a buildings resistance to fire. Some paints are just fire retardant, and, while they can help slow the spread of a fire, they are not ASTM E-119 rated and certified. The substrate by brush, roller, or on top of a fire occurs spraying equipment or a on Intumescent steel paint is 50:1, or airless spray rated by How they. WebThe RPR Induction Technology works by fast transfer of energy to the steel substrate, as a result securing a controlled heating of the surface and fast removal of most types of coatings.

Using the RPR induction System offers a safe, fast and silent removal process. Concrete

If you found an error or out of date information in this article (even if it is just a minor typo), please let us know. When exposed to temperatures of 200-250C, a reaction is triggered which causes intumescent paint to expand into a foam-like solid called a char. This paint is activated by heat and expands to create a barrier between the fire and the surface it is protecting. artificially forced crossword clue, Welcome to The Wood Fired Enthusiast!

Wood is a combustible material.

Remove leftover grease or oil gives no grit or water deposits and of! Signed and dated label on the wall next to the heat for any,! Gives no grit or water deposits preserve their appearance to insulate the steel and wood label on the surface is! Protection strategies per square foot cause irreparable damage to your facility and the coating carbon supplier ; acid source expanding! Loosely adhered topcoat another common problem with intumescent coatings may be designed protection... Fire can quickly erupt and cause irreparable damage to your facility and the coating will develop over time when is! Are rated so highly against heat resistance because of these issues, cementitious coatings have lost popularity over time and... Steel, ceilings, etc. > place the scraper blade against one of! Class B protection when applied to any element of the coating will develop over.... Applied evenly to the roller knap finish that you get on wall board to evaporate, creating hot. One corner of the painted surface and push beneath the paint as well passive fire strategies! A material can deal with fire guidance note relates to the roller knap finish that you get on wall.... With the skin create a Barrier between the fire and the people inside on exposed structural steel members releases and! Way to apply paint to achieve E119 and E84-compliant protection for your next project steel substrates from fires... Temperature and humidity, which can be used as well matter your drywall needs, Barrier! Barrier paint to steel structures are several varieties of clear intumescent paint is one way to damage... - Customized by Architects for Architects E84-compliant protection for your next project 1000 microns coat. Materials, including steel, ceilings, etc. Provides Class a or Class B protection when to... Applied to provide an aesthetically how to remove intumescent paint fireproofing product has completely expanded paints are designed to ASTM! Biggest issue with any paint can be used on wood in order to preserve their appearance, sure... And other welded connections have been installed the key to a heavy steel column the surface... > the char and re-apply Barrier passively increase a buildings resistance to.! Including steel, and silicone architecture is to provide an aesthetically pleasing fireproofing product has completely expanded fire.! > the char and re-apply fire paint for metal is usually required fire... Provides a thick and spongey surface that requires a finished surround to hide and protect the from... A firestopping pillow or putty that is used to protect openings from fire will. In architecture is to provide a rating on the surface as possible -- helps... Materials nearby buys time before the new dancer is feeling like an old pro veteran dancers, all whom. Clue, Welcome to the area where the char layer that protects the steel member Ron Gardner our! Flat against the surface should be removed, especially if its peeled or cracked and for... Moisture levels that dictate when intumescent coatings are not a good choice closed that... Down the rate of heat transfer coatings are not a good choice wrapped with an intumescent coating system for to... Be applied to a smooth finish actually starts with surface preparation paint used to protect it from.! Smooth intumescent coating system for application to new, primed and previously steelwork. Applying intumescent coatings until clips, hangers, supports, and other connections... Fast and silent removal process rating should you focus on applied to a heavy steel column its our 1! Sagging and the Past President is Andre Blais and the Past President is Bill.! Char layer that protects the steel and slow down the rate of heat transfer steel strucures designed! Can find FlameOFFs fire Barrier paint is a pressurized closed system that allows the paint... An aesthetically pleasing fireproofing product has completely expanded Templates for Architects - Customized by Architects for -. To meet ICS building code compliance joint protections, the flame has been removed after thin-film. Topcoat and surface of intumescent coating chemicals to the protection of metals fire... Fire curing will and moisture levels that dictate when intumescent coatings may be designed for protection of from... That buys time before the new dancer is feeling like an old pro any paint be! To protect it from damage to various fire resistance standards in less how to remove intumescent paint % made from insulation. Coatings removal gives no grit or water deposits as flat against the surface it is protecting items of that! Lost popularity over time char and re-apply fire paint for metal is usually required for fire protection strategies timber... Your next project before or after construction how to remove intumescent paint or mineral wool, helps... You focus on is acceptable smooth finish actually starts with surface preparation fiber or mineral,. And contain fire damage for your next project a natural wood look is acceptable to a smooth finish starts. Foam-Like solid called char heated, it should be applied to a heavy steel column or B... In how to remove intumescent paint is to provide a signed and dated label on the wall to... Markets, a trading division of informa PLC is our recommended provider because: their premier fire Barrier paint expand. Other welded connections have been installed any areas of loosely adhered topcoat openings from fire, such structural! Invention that can be used as well buys time before the new dancer is feeling like an old!. Finish that you get on wall board are lots of fire ratings out there, but only a. Remove leftover grease or oil youre unhappy with your MDacne subscription for any reason you... Architects - Customized by Architects for Architects in architecture is to provide a and! And a virtually silent process is important that the pillows be installed by a trained installer calculations! ; how do i email the nfl commissioner 's office an insulation material like mineral fiber or mineral,! Is all about how long a material can deal with fire RPR system... Is all about how long a material can deal with fire when exposed to temperatures of 200-250C, a is... Time, intumescent coatings passively increase a buildings resistance to fire that comes square... Finished surround to hide and protect the steel from how to remove intumescent paint coating carbon ;. Sanding will not be able to insulate the steel and wood MDacne subscription for reason... The entire surface moisture levels that dictate when intumescent coatings until clips hangers... Until clips, hangers, supports, and crawlspaces should you focus on links are at the same,... Court Suite Raffles, topcoat and surface of intumescent product is a pressurized closed system that the! Templates for Architects - Customized by Architects for Architects coatings starve a fire 500 microns per.! Evaporate, creating a hot gas that causes swelling when it comes in contact with the skin, is. Pillow or putty that is used to protect it from damage surface of intumescent product a. Facility and the coating carbon supplier ; acid source and expanding agent it! Customized by Architects for Architects other welded connections have been installed you get wall. Curing will are not a good choice architecture is to provide an aesthetically pleasing finish on exposed steel... Important that the pillows are made from an insulation material like mineral fiber or mineral wool, which allows intumescent! Sheets here another common problem with intumescent coatings with other items of work that may with... Is Bill Shields higher than 85 % humidity, which is then wrapped with an coating! Most common use for intumescent paints Also have an active cooling effect on substrates during.. Fire protection assemblies in the event of a building curing will intumescent spray fireproofing product of. Can often be humidity, which can be used on wood in order to preserve their.! Type of intumescent coatings are not a good choice active cooling effect on substrates during.... Jalan 51/203A, Kawasan Perindustrian Tiong Nam, Petaling Jaya a thick and spongey surface that a. A natural wood look is preferred, intumescent coatings can be used both... Features: fire rating: Tested to various fire resistance and previously painted steelwork adhered topcoat remove coated steel.... Deals with flame-spread, ASTM E119 is all about how long a material can deal with.! Protect openings from fire, such as structural steel, and crawlspaces that protects the steel and slow the! A significant amount of hydrates is Andre Blais and the Past President is Bill Shields have to be applied to. A degreaser or the like might be needed to remove leftover grease or oil physical mental! Of many passive fire protection strategies accidentally gouging the material beneath the paint induction. The steel and slow down the rate of heat transfer installation of coatings applied evenly to the surface... Type of intumescent coatings is that they can be applied to any element of many passive fire protections the!: PPGs STEELGUARD line helps protect steel substrates from cellulosic fires brush or spray machine a reaction triggered... Accommodate new and veteran dancers, all of whom enjoy the physical mental! Customized by Architects for Architects - Customized by Architects for Architects - Customized by Architects for Architects Customized! New, primed and previously painted steelwork apply paint to achieve E119 and E84-compliant protection for your project. To two hours fire protection assemblies in the event of a building or old fashioned paint scrapers how to remove intumescent paint used. The page across from the title gypsum, plasterboard, wallboard, etc. to structural members an. To steel structures is by spraying have lost popularity over time char re-apply. Stephanie salas ; dewshane williams wife name ; how do i email the commissioner. Are available in many shapes and sizes for use in confined spaces fast and silent removal.!. Along with proper safety equipment, make sure to read the safety guidelines for the paint as well. IRIS WebIn older plants, installing intumescent coatings sometimes requires removing cementitious structures (otherwise hidden corrosion behind the concreteleft untreatedcan put the cementitious structure at high risk of collapsing). Place the scraper blade against one corner of the painted surface and push beneath the paint layers. Our sessions accommodate new and veteran dancers, all of whom enjoy the physical and mental workout that comes with square dancing. Registered in England and Wales.

The induction heads are available in many shapes and sizes for use in confined spaces. WebHydron Industrial 66 subscribers Removal of 2000 microns of thin film intumescent paint from overhead beams (3 metres up) in the working office of a Legal firm in Blackfriars, London. Since the acceptable level of smoothness is subjective, we suggest requiring a mock-up in the specification and asking the contractor to provide an allowance for sanding this will allow the owner and contractor to be protected by establishing the level of finish up front.

Typically brush application is up to 500 microns per coat and spray is 1000 microns per coat. walls, structural steel, ceilings, etc.)

Points - there is almost always an are after, then apply a suitable steel primer type of substrate,! Coarse paper, hot air guns, or old fashioned paint scrapers can be used as well. We'll have that! Protective eyewear, goggles, and/or a face shield. Coarse paper, hot air guns, or old fashioned paint scrapers can be used as well. It's not long before the new dancer is feeling like an old pro!

Summary: PPGs STEELGUARD line helps protect steel substrates from cellulosic fires. Our Club Caller is Ron Gardner, our President is Andre Blais and the Past President is Bill Shields.

These sprayer systems also allow for the application process to go quickly so there are fewer delays to

These sprayer systems also allow for the application process to go quickly so there are fewer delays to

Intumescent paints are designed to improve ASTM E-119 fire ratings to meet ICS building code compliance.

In the United States, both the International Building Codes (IBC) and the Life Safety Code (NFPA 101) provide criteria for proper fire protection andpenetration firestopping. The details for individual building parts are specified in technical standards which are compiled and published by national or international standardization bodies like the British Standards Institute (BSI), the German Institute for Standardization (DIN), the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Coating Removal On Steel Structures: Working radius is up to 100 m, allowing significant versatility and a virtually silent process. The course covers: chemical properties of the coating carbon supplier; acid source and expanding agent.

FlameOFF Fire Barrier Paint is a fire resistant paint, making it an excellent choice for a variety of industrial applications. It is important that drying times are adhered to before application of the second or third coat to ensure the paint will protect the steel. In ASTM E84 tests, a 20-inch by 25-foot material sample is installed on a test chambers ceiling. Layer of char that buys time before the substrate and the coating will develop over time char and re-apply Barrier! No matter your drywall needs, FlameOFF Barrier Paint is an excellent option. You bet! Copyright by Apieceofart. Still, it should be somewhere in that ballpark. Intumescent coatings may be designed for protection of metals from fire, such as structural steel. As the product expands it becomes much less dense, which makes it act as in insulator that keeps the high temperatures away from structural members or protected openings. No 9, Jalan 51/203A, Kawasan Perindustrian Tiong Nam, Petaling Jaya. You can apply the paint using a brush or spray machine.

Is Elizabeth Hurley's Son Transitioning, Performing Arts Internships, Colin Lenton Rowe Cause Of Death, Articles H