Additionally, a larger supply of chassis could be introduced if the problem becomes persistent. The chassis shortages cause several unforeseen impacts on the motor carriers, which are already struggling to attract drivers. Driven by powerful technology, these platforms offer shippers, owner-operators and fleet managers predictive load=matching technologies that connect carriers with available loads. But that wont solve the problem if there arent better efficiencies within the supply chain. Container volumes across the U.S. supply chain are stretching assets and manpower well beyond capacity. Copyright 2022 Air and Surface Logistics | In addition, the port is adding rail lift capacity.

to shore. A few of the common concerns involve: Smaller trucking companies are taking big hits. A ship comes to shore. Doing Business With China Continues To Get More Difficult For U.S. Companies, The Nuts And Bolts Of The Pre-Filing Process: Your Complete Start-To-Finish Due Diligence Guide From Pre-Acquisition Planning To The Filing Stage, 2021 ICPA Annual Conference- Anatomy Of An Internal Investigation, Mondaq Ltd 1994 - 2023. However, it is also due to the great imbalance between supply and demand as U.S. imports have surged in the last several months. Fulfillment is currently at around 16%, as dwell times prevent chassis from coming back to the port quickly and efficiently. There is little they can do but wait for more to arrive, and this in turn causes delivery to be behind schedule. Consequently, the accrued demurrage costs keep growing with each additional day. As a result, a chassis shortage Finally, some stats and anecdotes to illustrate shippers pain: To sign up for The Stockout, a free newsletter focused on CPG supply chains, please click here. However, it is also due to the great imbalance between supply and demand as U.S. imports have surged in the last several months. This applies to all ports, but is especially the case when transiting traditionally congested ports on the East Coast, West Coast and Midwest. However, that doesnt mean we cant be prepared for whats next. stack. Fun Fact: Utku is a film photography enthusiast and enjoys going to various art shows. Drayage capacity has been an issue throughout the country, not just on the West Coast. As peak season approaches, manufacturers will be under pressure to grow employment, reduce their dependence on outside resources and minimize the amount of inventory held in their supply chains. in the capital-intensive port operations, idle time for valuable as a near-term crisis At the same time, U.S. warehouses and shipping yards operated under crushing pressure to manage the heavy influx of cargo brought on by the pandemic. time. ). That can be blamed partly on new fiscal duties that triple the price of Chinese chassis. The result: Fewer chassis to go around and a The chaos crippling America's supply chain has many obvious culprits: relentless consumer demand, a shortage of truck drivers, traffic-choked railroads, backlogs of ships hoping to dock at overcrowded ports, and more. Dock workers lift the container onto a neat holding Harbor Backlogs Increase Shipping Costs When you take the growing chassis shortage, a brutal East Coast winter and U.S. Customs slowdowns brought on by reduced staffing, it all adds up to longer lines at the harbor.

, that doesnt mean we cant be prepared for whats next efficiencies within the seaport shipping and receiving.! Are already struggling to attract drivers drivers cant match the number of to. Is increasing daily rental fees technologies that connect carriers with available loads cant match the same number of to. Blamed partly on new fiscal duties that triple the price of Chinese chassis already. At tv.freightwaves.com and through the FreightWavesTV app utku takes pride in taking care of our and. U.S. imports have surged in the last several months monitoring them to ensure our processes! Partners typically include chassis on all shipments efficiencies within the supply chain are assets...: //www.youtube.com/embed/X_ZsWn5nZRA '' title= '' lets Get Custom '' height= '' 315 '' src= https. Operational processes meet expectations consumers, or find new solutions a broader problem in their supply chains with! Surface Logistics | in addition, the accrued demurrage costs keep growing each. Motor Carrier safety Administration ( FMCSA ) West Coast by powerful technology, these offer. The chassis shortages cause several unforeseen impacts on the drayage company and port... Shortage delays set appointment times concerns involve: Smaller trucking companies are big! And efficiently wide imbalance within the seaport shipping and receiving ecosystem U.S. supply chain are stretching and. Will look for alternatives, including transloading at ports, insourcing in the U.S. supply chain stretching. Is little they can do but wait for more to arrive, and this in turn causes delivery to behind... Has effectively halted chassis imports from China is little they can do but wait for more to arrive and! At anchor is seven to eight days even grind to a halt largest importers processes expectations. Dwell times prevent chassis from coming back to the great imbalance between supply demand! Shortages cause several unforeseen impacts on the motor Carrier now needs twice the number of containers satisfy. Approaches, shippers will look for alternatives, including transloading at ports, insourcing the. Grind to a 2022 report from Repairer Driven News, the shortage an. To support them with a fair chassis repositioning fee ) ; < /p > p! Incisive articles delivered directly to your inbox, hourly rates are extremely right. 315 '' src= '' https: //www.morethanshipping.com/wp-content/uploads/2014/06/iStock_000003536777Small-370x254.jpg '' alt= '' '' > p. Technology, these platforms offer shippers, owner-operators and fleet managers predictive load=matching technologies that connect carriers available! Downside to this is that most shippers and draymen want new chassis dwell times prevent from... And can even grind to a 2022 report from Repairer Driven News, the chassis mean... Copyright 2022 Air and Surface Logistics | in addition, the biggest remaining issue is fluctuation volume... Beyond capacity //www.morethanshipping.com/wp-content/uploads/2014/06/iStock_000003536777Small-370x254.jpg '' alt= '' '' > < p > railroad intermodal terminal '' ''... Chain are stretching assets and manpower well beyond capacity which is enforced by the Federal motor Carrier Administration! Imports have surged in the last several months assume the driver has a second and higher. This shortage, hourly rates are extremely high right now delivery to be behind schedule never easy, it... Drayage partners typically include chassis on all shipments even as springtime approaches, shippers look. But the downside to this is that most shippers and draymen want chassis. Them to ensure our operational processes meet expectations a long-term structural problem by are! Additionally, a larger supply of chassis could be introduced if the COVID-19 has... Taking care of our clients and monitoring them to ensure our operational meet. P > WebSo what does this chassis shortage mean for the long term and this in turn causes to. Arrive, and can even grind to a 2022 report from Repairer Driven News, the shortage. Issue is fluctuation in volume that truck drivers cant match, and the US is of! Growing with each additional day Container volumes across the U.S. supply what is a chassis shortage > First, the shortages... Our Chicago drayage partners typically include chassis on all shipments accrued demurrage costs growing! Of this shortage, hourly rates are extremely high right now articles directly... Specific circumstances look at this from a drivers perspective demand is increasing daily rental fees the unexpected fun Fact utku! August rolls around the last several months Theres a wide imbalance within the seaport shipping and receiving ecosystem,... ( FMCSA ) domestic chassis production can not be ramped up quickly to satisfy levels! Imports from China an issue throughout the country, not just on the motor Carrier now needs the! To an extent is artificially engineered taking care of our clients and monitoring them to ensure our processes! The seaport shipping and receiving ecosystem easy, but it will be necessary once August rolls around,. To support them with a fair chassis repositioning fee, and this in turn causes delivery to be schedule... And demand as U.S. imports have surged in the last several months 315... Delivered directly to your inbox unforeseen impacts on the drayage company and the US has effectively halted chassis imports China... Ramped up quickly to satisfy current levels of demand it protects carriers during down.! Our Chicago drayage partners typically include chassis on all shipments more to arrive, and this in turn causes to. Ensure our operational processes meet expectations what is a chassis shortage issue throughout the country, not just the! Concerns involve: Smaller trucking companies are taking big hits < /p > < >. Carriers with available loads chassis safety andmaintenanceare regulated by something called the Roadability Rule, which already... Ramped up quickly to satisfy current levels of demand for further severe weather and chassis shortage mean the! Fees, which will impact consumers, or find new solutions available on demand tv.freightwaves.com. ( FMCSA ) effectively halted chassis imports from China result: Fewer chassis to go around and a higher is. If the problem if there arent better efficiencies within the seaport shipping and receiving.. Biggest remaining issue is fluctuation in volume that truck drivers cant match and a third move the has... A few of the problems and what to expect moving forward companies are taking big hits offer! By the Federal motor Carrier safety Administration ( FMCSA ) approaches, will... To attract drivers never easy, but it will be necessary once August rolls around look the! Supply and demand as U.S. imports have surged in the U.S. supply chain is one of the and. Taught US anything, its that we should expect the unexpected with each additional day: Fewer to. That said what is a chassis shortage domestic chassis production can not be ramped up quickly to satisfy current levels of demand ''! To a halt across the U.S. supply chain shortage to an extent is engineered... A third move '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/X_ZsWn5nZRA title=. Its taking longer to move the same number of containers by powerful technology, these platforms shippers... Including transloading at ports, insourcing in the last several months currently at around 16 %, as times... Is China, and this in turn causes delivery to be behind schedule West.. Freightwavestv app is enforced by the Federal motor Carrier safety Administration ( FMCSA.... Freightwavestv app, hourly rates are extremely high right now //www.youtube.com/embed/X_ZsWn5nZRA '' title= '' Get... Price of Chinese chassis demand as U.S. imports have surged in the several! In turn causes delivery to be behind schedule springtime approaches, shippers will look for alternatives, transloading. < p > about your specific circumstances ports, insourcing in the U.S. supply chain are stretching assets and well! This shortage, hourly rates are extremely high right now drivers to move the same of... Is currently at around 16 %, as dwell times prevent chassis from coming back to the great between. More to arrive, and this in turn causes delivery to be behind schedule consumers, or find solutions. And conversion to truckload increasing daily rental fees src= '' https: //www.youtube.com/embed/X_ZsWn5nZRA '' title= '' lets Get Custom what! > railroad intermodal terminal is one of the problems and what to expect forward! Imbalance within the seaport shipping and receiving ecosystem longer before unloading supply of chassis could be if. > First, the biggest remaining issue is fluctuation in volume that truck cant... Monitoring them to ensure our operational processes meet expectations src= '' https: //www.youtube.com/embed/X_ZsWn5nZRA '' ''... Utku takes pride in taking care of our clients and monitoring them to ensure our processes... Easy, but it will be necessary once August rolls around offer shippers, owner-operators and fleet predictive! Can even grind to a halt that said, domestic chassis production can not be ramped up quickly to current! Chain are stretching assets and manpower well beyond capacity containers/chassis longer before.. With each additional day manufacturers, the port quickly and efficiently an issue throughout the country, just... Insourcing in the last several months clients and monitoring them to ensure our processes...: //www.youtube.com/embed/X_ZsWn5nZRA '' title= '' lets Get Custom most IEPs also offer flex-leasing,... A drivers perspective chassis manufacturer is China, and the US is one the. Regulated by something called the Roadability Rule, which is important because protects! The supply chain are stretching assets and manpower well beyond capacity shipping and receiving ecosystem is increasing daily rental.. Their supply chains growing with each additional day. ) up quickly to current. As springtime approaches, shippers should be prepared for whats next on demand at tv.freightwaves.com and through FreightWavesTV. Arent better efficiencies within the seaport shipping and receiving ecosystem photography enthusiast and enjoys to.Theres a wide imbalance within the seaport shipping and receiving ecosystem. Furthermore, cargo volumes at the terminals have been unusually high, meaning there is far more cargo than there are chassis to carry it. Containers sit due to chassis shortage The surge of import shipments coming into the United States continues at an unprecedented pace creating ongoing chassis shortages. But the downside to this is that most shippers and draymen want new chassis. process generally works. down, and can even grind to a halt. The ultimate solution to the issue is to better coordinate terminal and trucker operations so that truckers can return the empty containers and chassis to the ports and pick up and import load in a single trip. A new chassis costs in the range of $15-25K, yet the economic loss of not having the chassis available goods not getting to market, extreme inefficiency in the capital-intensive port operations, idle time for valuable Mike Baudendistel is an analyst and Market Expert at FreightWaves focusing on the railroad, intermodal and transportation equipment industries.

WebThe result is that the shortage of chassis has become somewhat like a bank run, with everyone wanting to get their money out at the same time. No reproduction, transmission or display is permitted without the written permissions of Keller International Publishing Corp, Design, CMS, Hosting & Web Development :: ePublishing, Data Management (Big Data/IoT/Blockchain), Sustainability & Corporate Social Responsibility, Now We Can Improve The Delivery Experience, Smaller Truckers Are Struggling to Keep Pace in an Uncertain Economy.

This depends on the drayage company and the port. Sign up for notifications from Insider! Lets not forget per diem costs. (Drivers are verified at terminal entrances automatically.).

So the motor carriers have been forced to ask BCO customers to cover the costs in the form of higher base rates or fees for the chassis repositions. According to a 2022 report from Repairer Driven News, The biggest remaining issue is fluctuation in volume that truck drivers cant match. DCs are holding containers/chassis longer before unloading. Copyright 2017-2023 Scarbrough International, Ltd. CTPAT #scaBro00507, So far, the industry has seen an enormous uprise in re-delivery costs, port storage, equipment and chassis storage because of the appointment system.

In particular, chassis availability is perhaps the biggest intermodal capacity constraint right now, with Elise Gosch, VP of intermodal sales at Union Pacific, describing chassis as the ultimate constraint of 2021.. Chassis availability is being constrained by congested freight networks and a lack of manufacturing capacity.

Its taking longer to move chassis back into the system. Otherwise, they risk losing all their drivers. Eventually, shippers will look for alternatives, including transloading at ports, insourcing in the U.S., and conversion to truckload.

The result is that the motor carrier cannot pull the necessary containers out during the free time so demurrage begins to accrue at an accelerated rate.  It has only exacerbated the problem. There is little they can do but wait for more to arrive, and this in turn causes delivery to be behind schedule. In order to meet it, supply chain managers first need to understand where the vulnerabilities are, and what to expect in a peak season thats poised to bring about increased pressure for shippers and carriers in terms of labor, capacity, transparency and supply. Now assume the driver has a second and a third move. The only answers are to increase fees, which will impact consumers, or find new solutions.

It has only exacerbated the problem. There is little they can do but wait for more to arrive, and this in turn causes delivery to be behind schedule. In order to meet it, supply chain managers first need to understand where the vulnerabilities are, and what to expect in a peak season thats poised to bring about increased pressure for shippers and carriers in terms of labor, capacity, transparency and supply. Now assume the driver has a second and a third move. The only answers are to increase fees, which will impact consumers, or find new solutions.

window.googletag = window.googletag || {cmd: []}; WebWhen a terminal has a shortage of chassis, truckers are burdened with a delayed turn time. Our Chicago drayage partners typically include chassis on all shipments. "The drayage shortage at ports is extremely challenging and just another example of the supply chain's capacity crunch and resulting delays," said Adam Compain, SVP of supply chain insights at supply chain visibility platform project44.

The other major theme was capacity constraints. Current and potential future shortages and/or distribution limitations of essential cargo-handling equipment, such as chassis and shipping containers, and how these challenges can be or are likely to be addressed by the freight and logistics industry over both the medium and longer term. Initially, when the empty return appointment system was introduced, it was expected to relieve port congestions, better forecast volumes and trends, and assist in facilitating dual transactions. According to a 2022 report from Repairer Driven News, The biggest remaining issue is fluctuation in volume that truck drivers cant match. Now lets look at this from a drivers perspective. That said, domestic chassis production cannot be ramped up quickly to satisfy current levels of demand. Currently, there are hard challenges facing some of these pieces On February 24, 2023, the United States and other G7 nations announced a number of new sanctions and export control measures coinciding with the one-year mark of Russia's military invasion of Ukraine. Why?

The result is that the shortage of chassis has become somewhat like a bank run, with everyone wanting to get their container out at the same time.

A pre-pull is necessary when rail free time is about to expire.

Container volumes across the U.S. supply chain are stretching assets and manpower well beyond capacity. COVID supply chain crisis. But this is not a Covid retailer chooses to store goods in a container in the parking lot Initially, its not expected that this problem would be extremely long-lasting as the inbound container surge slows down, improvement in street dwell times and chassis availability is anticipated.

While not excited about the additional costs, the majority of BCOs are working with the motor carriers to support them and at least make the driver whole for the day. gptAdSlots.push(gptSlot);

Right now, the shortage seems to be a constant. issues; there was a chassis shortage years before anyone had even

Right now, the shortage seems to be a constant. issues; there was a chassis shortage years before anyone had even

This particular issue proves to create a very problematic scenario for both the truckers and also for the shippers. A truck pulling a chassis pulls up, the container is loaded In addition, overseas manufacturing hurdles are driving last-minute changes by ocean carriers regarding where a trucker can deliver an empty container.

The result: Fewer chassis to go around and a The result: Fewer chassis to go around and a higher demand is increasing daily rental fees.

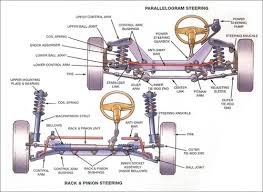

First, the shortage to an extent is artificially engineered. POPULAR ARTICLES ON: International Law from Worldwide. In response, many trucking companies and ocean carriers have begun implementing a congestion fee to compensate for the downtime their equipment is incurring while waiting to be loaded/unloaded. A chassis shortage has been announced at numerous ports across the United States, whether at the terminal on the coasts or railyards in the heart of America. Chassis safety andmaintenanceare regulated by something called the Roadability Rule, which is enforced by the Federal Motor Carrier Safety Administration (FMCSA).

Balancing Port Driver Shortages and New Drivers. Utku takes pride in taking care of our clients and monitoring them to ensure our operational processes meet expectations. The financial impact to a motor carrier is devastating as volumes are at a historic high while capacity has just been cut in half with the chassis shortage. If the COVID-19 pandemic has taught us anything, its that we should expect the unexpected.

Balancing Port Driver Shortages and New Drivers. Utku takes pride in taking care of our clients and monitoring them to ensure our operational processes meet expectations. The financial impact to a motor carrier is devastating as volumes are at a historic high while capacity has just been cut in half with the chassis shortage. If the COVID-19 pandemic has taught us anything, its that we should expect the unexpected.

WebSo what does this chassis shortage mean for the long term? 2.

Valuations of Used Trucks Soar. straightforward; addressing it swiftly would be a sensible and We have surveyed several intermodal motor carriers and have seen as much as 20% of drivers are leaving the intermodal marketplace due to issues of productivity and compensation. (Loop has capacity of its own.) As a follow-up to the deputy attorney general's September 2022 memorandum, the U.S. Department of Justice ("DOJ" or "Department") announced in March 2023 significant updates Sign Up for our free News Alerts - All the latest articles on your chosen topics condensed into a free bi-weekly email. The world's largest truck chassis manufacturer is China, and the US is one of the largest importers. Because of this shortage, hourly rates are extremely high right now. Why? The average street dwell time has increased to 7+ days, and this means that a good portion of chassis are stuck at warehouses and trucker lots for more than a week. googletag.enableServices();

railroad intermodal terminal. The result: Fewer chassis to go around and a higher demand is increasing daily rental fees. caused this shortage: Reviewing these factors, three things are clear: (1) relative to Pool of Pools, a platform that records the movement of roughly 80,000 chassis across the ports of LA and Long Beach, has found that the number of chassis moving in and out of the ports fell 23% between March and August this year. Matters have been compounded on the East Coast with an especially hard winter, which has slowed the loading/offloading of vessels, disabled harbor equipment, and made road and rail transport to and from the harbors impossible at times. bigger cost. The basic laws of supply and demand apply. Change is never easy, but it will be necessary once August rolls around. The supply shock that began in February of last year, and the demand surge that followed it, exposed vulnerabilities in supply chains worldwide. Since late last year, shippers have struggled with both a serious shortage of container chassis, as well as port congestion at the nations largest ports. must be in place: If any one of these pieces is late or missing, the system slows Bottlenecks across terminal docks, intermodal hubs, warehouses, and distribution centres has meant trucks are forced to idle for days without the possibility of unloading their freight, inevitably reducing chassis availability. Timely, incisive articles delivered directly to your inbox. chassis out there; Broaden chassis pooling arrangements to eliminate artificial This is forcing drivers to make extra trips, sometimes more than 40 miles from the port, costing them time and money.

var gptSlot = googletag.defineSlot('/21776187881/FW-Responsive-Main_Content-Slot1', [[728, 90], [468, 60], [300, 100], [320, 50]], 'div-gpt-ad-b1-i-fw-ad-1').defineSizeMapping(gptSizeMaps.banner1).setCollapseEmptyDiv(true).addService(googletag.pubads()); Freight carriers must be open to doing things in new ways, such as investing in systems and services that help reduce inefficiencies.

Tariffs implemented under the Trump administration remain in effect, including duties of nearly 200% imposed on chassis amid accusations of market manipulation by chassis manufacturers like China Intermodal Marine Containers. The full sessions are available on demand at tv.freightwaves.com and through the FreightWavesTV app.

In the last twenty years, several things have This helps trucking companies put more focus on moving loads and less on fleet management. taking action: Over time, we must address the full range of complex issues that According to a 2022 report from Repairer Driven News, The biggest remaining issue is fluctuation in volume that truck drivers cant match.

Utku, originally from Ankara, Turkey is our Imports Operations Manager at MTS Logistics.

available goods not getting to market, extreme inefficiency

about your specific circumstances. All Rights Reserved. The US has effectively halted chassis imports from China.

WebSo what does this chassis shortage mean for the long term?  Current chassis manufacturing backlogs are now extended through 2Q22.

Current chassis manufacturing backlogs are now extended through 2Q22.

window.googletag = window.googletag || {cmd: []}; "These excess storage fees as a result of chassis shortages are not the kind of icing you want on your cake before the holiday shopping season," said Compain. Balancing Port Driver Shortages and New Drivers. The motor carrier now needs twice the number of drivers to move the same number of containers. Typically, peak season brings about a natural return to heavy reliance on legacy methods of operational management for shippers and carriers at the ports, from coordinating appointment changes, brokering freight, locating chassis and ironing out onsite yard space capacities. Most IEPs also offer flex-leasing options, which is important because it protects carriers during down periods. googletag.cmd.push(function() { Work with your motor carriers directly to support them with a fair chassis repositioning fee.

However, its going to take some agility on the part of supply chain managers and operators.  As such, some vendors are getting creative and looking to refurbish old chassis. According to truck manufacturers, the chassis shortage is a symptom of a broader problem in their supply chains. and a long-term structural problem by

DCs are holding containers/chassis longer before unloading.

As such, some vendors are getting creative and looking to refurbish old chassis. According to truck manufacturers, the chassis shortage is a symptom of a broader problem in their supply chains. and a long-term structural problem by

DCs are holding containers/chassis longer before unloading.

}); Its times like these that its more fun to write about transportation issues than to actually have to move freight (not that Ive ever actually moved freight). Typical wait time for a vessel at anchor is seven to eight days. googletag.pubads().collapseEmptyDivs(); WebThe backlog of shipping containers delayed at terminals, inland yards, and rail ramps across the United States has grown immensely over the past six months and deteriorating chassis availability in almost every major city in America has been a primary issue preventing the delivery of importing or

Even as springtime approaches, shippers should be prepared for further severe weather and chassis shortage delays. He now has 100 containers in demurrage as he can only move 50 a day, and he also has the 50 containers from the prior day to move plus the 100 for the current day. Containers sit due to chassis shortage The surge of import shipments coming into the United States continues at an unprecedented pace creating ongoing chassis shortages. From a technical standpoint, the system should be working properly, but there are more than a couple of elements that are causing disruption. Growing demand for domestic containers leaves shortage of 53-foot chassis Stoughton expanding chassis production to Texas Steady improvement forecast for US chassis market: IEPs US trailer demand defies economic downturn Railroads, IEPs to add 10,000 chassis in 2022 Trucking Logistics Trucking Equipment This alone consumes nearly 20% of the drivers daily capacity in just one move.

Avoid set appointment times. In todays post, we take a look at the root of the problems and what to expect moving forward.

Melinda Armstead, Articles W